best-selling furnaces

hardening furnaces

air-circulation furnaces

large air-circulation furnaces up to 300° C

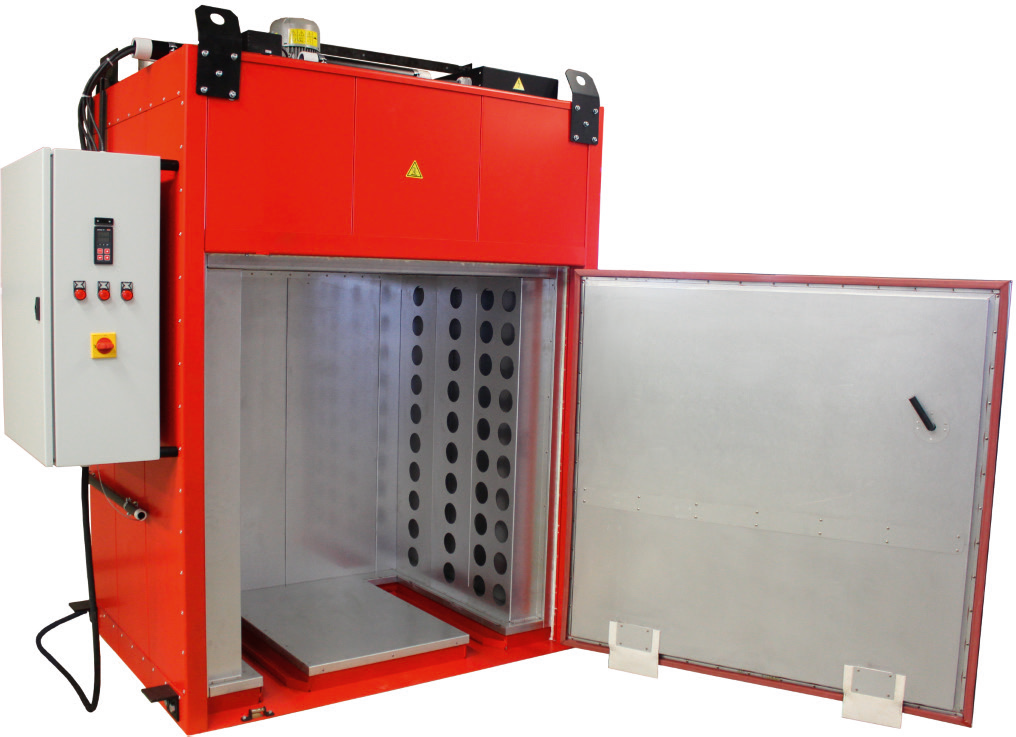

chamber furances for ceramics

bogie hearth furnaces

Arnold Schröder Industrieöfen GmbH

Founded in 1978 by Arnold Schröder, the family business Arnold Schröder Industrieöfen GmbH has established itself on the market as an internationally active company for industrial furnaces over the past 40 years. In addition to industrial furnaces for the heat treatment of metal, Arnold Schröder Industrieöfen GmbH also offers industrial furnaces for ceramics, glass, dental, plastics and many other areas. The industrial furnaces are used by customers in production as well as in laboratories and in research and development. The kilns are also used in the school, art and hobby sectors.

The industrial furnaces from Arnold Schröder Industrieöfen GmbH are mainly used for hardening, annealing, tempering, annealing, ageing, drying, preheating, melting, but also for firing, decorating, bending, curving, annealing, fusing, sintering, debinding, baking, ashing and for a variety of other applications.

Flörsheim am Main in the Rhine-Main region and the heart of Germany offered the perfect conditions for founding the company. Professional expertise and a high level of service orientation combined with geographical proximity to potential customers allowed the company to grow rapidly, so that the first company locations in Eichendorfstraße and Fuchstanzstraße quickly became too small. In 1989, the property with office building, workshop and warehouse at Hafenstraße 10 in Flörsheim was completed, which still serves as the company headquarters today. In 2004, the son Markus Schröder took over the management of the company from the founder and is also responsible as a shareholder in the 2nd generation.

Competent advice and excellent service from qualified employees form the foundation of high customer satisfaction. As the former service manager of a large industrial furnace manufacturer, Arnold Schröder has had extensive expertise in furnace technology, temperature control and thermal process engineering right from the start. This benefited both the customers and the company’s employees. Competent customer advice and service orientation are the basis of the sustained success of Arnold Schröder Industrieöfen GmbH. Not only are new furnaces sold, but many furnace spare parts such as heating elements, support tubes, control systems etc. for most furnace models are always in stock. Many repairs – from replacing heating elements and electrical work to the complete relining of ovens – are carried out on site at the customer’s premises or after delivery to the headquarters in Flörsheim. The Arnold Schröder Industrieöfen GmbH customer service department can also carry out repairs to third-party ovens from e.g. Nabertherm, Helmut Rohde, Kittec, LAC, SNOL, Snjstaal, Eliog, David & Baader and other manufacturers.

The company’s flat hierarchies are consciously practiced and promoted. Thanks to short decision-making processes, the entire company is able to act quickly and can advise interested parties individually on site or at the headquarters in Flörsheim on the purchase of a suitable industrial oven or support them with oven repairs and spare parts supply.

Identification with the company is a matter of course at Arnold Schröder Industrieöfen GmbH. The employees, most of whom have been with the company for many years, enjoy the informal working atmosphere and the excellent career opportunities. It is therefore not surprising that some families of employees are already the second generation to work for the company. Through qualification measures, the company has repeatedly succeeded in filling management positions with its own employees, thus maintaining and expanding the company’s future with expertise and experience.

Corporate communication at Arnold Schröder Industrieöfen GmbH is modern and digital. Interested customers can be offered intelligent digital solutions such as connection to a network or MDE by trained specialist personnel. For example, digital remote access for maintenance purposes is possible. The shortened response times on this basis help to minimize downtimes and save resources.

Sustainability is an important topic at Arnold Schröder Industrieöfen GmbH. Both the management and the entire team are motivated to put environmental friendliness into practice. For this reason, attention is not only paid to tailor-made and energy-saving solutions when developing new products and advising customers, but also within the company itself. Electric vehicles are used wherever possible and a photovoltaic system is being planned for the roof of the company building in order to conserve resources and work in a cost-conscious manner.

We offer high-quality spare parts for industrial furnaces and kilns from various manufacturers. Short delivery times are guaranteed by a large stock of spare parts and our own production of heating coils.

All the information you need to order the required spare parts or book an appointment can be found on the type plate on the kiln. The type plate is usually located on the door of your industrial oven/oven, near the door or on the back. On the type plate you will find the oven model, the year of manufacture and the serial number. Please provide us with this information and the manufacturer of the oven with your inquiry and feel free to send us a few photos. You will then quickly receive a suitable spare parts quote and can order it directly. If you are unsure or cannot carry out a repair yourself, please call us directly.

Customer service

Repairs

If necessary, we carry out repairs with our experienced service technicians. If feasible, only the actually defective components on the oven are replaced in order to keep downtime and costs as low as possible. However, if necessary or requested by the customer, we also carry out “complete refurbishments”. For small ovens and complex repairs, it makes sense and is also the most cost-effective solution to carry out the work in our workshop. Travel costs are avoided and, if necessary, special parts can be made to measure.

We are happy to support our customers with preventive measures to minimize the risk of failure and increase system safety.

maintanance contracts

In addition to extending the service life of your industrial furnace or kiln and increasing system availability, maintenance contracts have other advantages:

- We remind you in good time that regular maintenance is due

- You benefit from our experience and expertise and can thus optimize your operating processes

- Operational safety is improved, as a regularly maintained kiln poses fewer risks

- Our experienced service staff are familiar with the requirements and dangers of oven repairs and maintenance. Many jobs require the removal of protective covers that cover dangerous machine parts

- If damage does occur, regular and documented maintenance serves as proof for insurance companies and employers’ liability insurance associations

Deutsch

Deutsch